Choosing the right wheel and tire

Trying to find the right wheel for your vehicle, terrain or application?

We can help with that. Because we too know the difficulty in choosing the right wheel or tire for our vehicles. Seriously, every year the list of options gets bigger. And, if you are into following the latest trends, well those change on a regular basis as well.

Hopefully we can help narrow it down a bit: For the most part, it really starts by knowing what application your vehicle has.

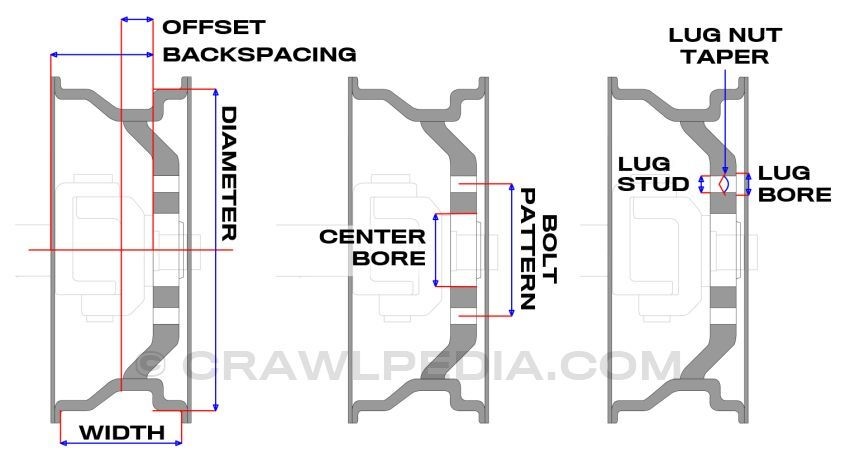

Bolt Pattern: What bolt pattern does your year, make and model have. Assuming it is still running stock hubs. If not, and you have gone to the wild side, and your rig is now completely built, what is the bolt pattern for it now? Your bolt pattern is going to narrow down your search to the specific wheel that will bolt (lug nuts) onto your hub.

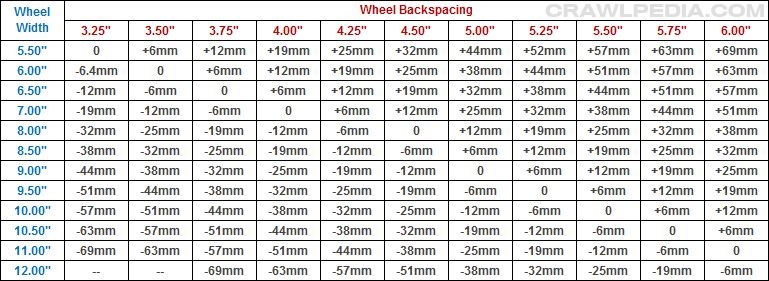

Backspacing & Offset: Knowing what backspacing and offset your vehicle has, or can handle without rubbing on your fender wells for example, may be your next step. Backspacing and offset will determine how far inward, or outward from the center of your hub, the wheel will be. Also known as “stance”. Offset is the amount (usually measured in millimeters) of distance that the mounting surface of the wheel is away from the center-line of the wheel.

In layman’s terms, with a negative offset (-47mm) your wheel will stick out further from the vehicle, giving you a wider stance. A positive (+12mm) will do the opposite, putting the wheel closer toward the vehicle.

Wheel Diameter: Diameter can play a factor in your decision. Especially if you are thinking about going with a different size wheel. Manufactures build to demand. If the demand is for a 17″ diameter wheel (currently is) versus a 16″ diameter, you will have more options for the 17″.

The 17″ is a common size for today’s off-road enthusiasts, as well as competitive racers.

Wheel diameter plays an important role with style and look. Over the years, we have seen larger size wheels being more common on trucks that are going for the tricked-out look, ya know, rolling on 20s. Maybe it’s 24s now… I might be a bit old school.

Other Factors: There are certainly other factors to consider, including cost, strength, weight, aesthetics, width, and where to buy, which is a given… Reno Off-Road (Parts & Accessories), I know a guy.

The above basic info info should help you narrow down your search, by helping you search for wheel that fits your application. Below we will give you the vehicles pattern charts and a great article on choosing the type of wheel you want or need.

What Next? Maybe you are trying to decide if you want steel, cast-aluminum or forged-aluminum.

How About Beadlocks? Do you treat it like you stole it, or compete in rock, desert or other competition racing, and need a beadlock to get you to the pits if / when you shred a side wall?

Shameless plug…. In 3, 2, 1, Reno Off-Road www.renooffroad.com sell them all.

HOW TO CHOOSE YOUR BOLT PATTERN, BACKSPACE OFFSET AND MORE.

Jason Baden (yeah, that’s me) has provided a detailed breakdown below. With the help of crawlpedia.com. Jump right to it on our site > Wheel Bolt Pattern, Backspace and Offset Guide.

Most Common Bolt Patterns

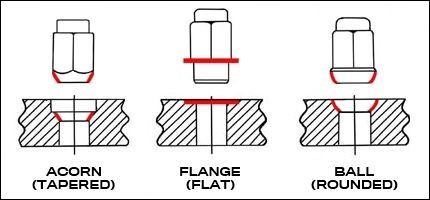

Most Common Lug Nut Types

Bolt patterns with an even number of lugs are measured from bolt center to bolt center while 5 lug bolt patterns are measured from the top of the upper lug to the center of the lower lug. To find your bolt pattern, measure the distance as accurately as possible and then find the corresponding bolt pattern in the conversion table below. For example, if you have a 5 lug wheel and your measurement is 5" then your bolt pattern is 5 x 5" (5 x 127mm).

Bolt patterns with an even number of lugs are measured from bolt center to bolt center while 5 lug bolt patterns are measured from the top of the upper lug to the center of the lower lug. To find your bolt pattern, measure the distance as accurately as possible and then find the corresponding bolt pattern in the conversion table below. For example, if you have a 5 lug wheel and your measurement is 5" then your bolt pattern is 5 x 5" (5 x 127mm).Bolt Pattern Conversion Chart

Wheel Backspacing & Offset Conversion Chart

Wheel Dimension Guide

Bolt Patterns Listed By Vehicle

| Chevy and GMC Trucks and SUV | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| 1/2 Ton Blazer, Jimmy, Suburban (2WD) | ’71-’91 | 5 x 5″ | 1/2-RH | Nut | 78.1mm |

| 1/2 Ton Blazer, Jimmy, Suburban (4X4) | ’71-’91 | 6 x 5.5″ | 7/16-RH | Nut | 108mm |

| Chevy & GMC 1/2 Ton Blazer, Jimmy | ’71-’91 | 5 x 5″ | 1/2-RH | Nut | 78.3mm |

| Chevy & GMC 1/2 Ton Blazer, Jimmy | ’71-’91 | 6 x 5.5″ | 7/16-RH | Nut | 78.3mm |

| 1/2 Ton Blazer, Suburban, Tahoe (2WD) | ’00 & Older | 6 x 5.5″ | M14 X 1.5 | Nut | 78.1mm |

| 1/2 Ton Blazer, Suburban, Tahoe (4×4) | ’92 & Older | 6 x 5.5″ | M14 X 1.5 | Nut | 78.1mm |

| Chevy & GMC 1/2 Ton Blazer, Jimmy | ’00 & Older | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy & GMC 1/2 Ton Trucks (2WD) | ’67-’87 | 5 x 5″ | 1/2-RH | Nut | 78.3mm |

| Chevy & GMC 1/2 Ton Trucks (4X4) | ’67-’87 | 6 x 5.5″ | 7/16-RH | Nut | 108mm |

| Chevy & GMC 1/2 Ton Trucks (2WD) | ’67-’87 | 5 x 5″ | 1/2-RH | Nut | 78.3mm |

| Chevy & GMC 1/2 Ton Trucks (4X4) | ’67-’87 | 6 x 5.5″ | 1/2-RH | Nut | 78.3mm |

| Chevy & GMC 1/2 Ton Trucks (2WD) | ’88-’98 | 5 x 5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy & GMC 1/2 Ton Trucks (4×4) | ’88-’98 | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy & GMC 1/2 Ton Trucks | ’99 & Older | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy & GMC 1/2 Ton Trucks (2WD) | ’88-’98 | 5 x 5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy & GMC 1/2 Ton Trucks | ’99 & Older | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy & GMC 1/2 Ton Trucks (4×4) | ’88-’98 | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy & GMC 3/4 Ton Trucks | ’76 & Older | 6 x 5.5″ | 1/2 or 14 | Nut | 78.3mm |

| Chevy 3/4 Ton Trucks (2500, K Series) | ’88-’00 | 6 x 5.5″ | M14 X 1.5 | Nut | 100.7mm |

| Chevy 2500 & 3500 Trucks (SRW) | All | 8 x 6.5″ | M14 X 1.5 | Nut | 117mm |

| Chevy Avalanche | ’02 & Older | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy Avalanche 1500 | ’02-’06 | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy Avalanche 2500 (4X4) | ’02-’08 | 8 x 6.5″ | M14 X 1.5 | Nut | 125mm |

| Chevy C1500 Truck (2WD) | ’88-’98 | 5 x 5″ | M14 X 1.5 | Nut | 78.1mm |

| Chevy C2500 Truck (2WD) | ’88-’00 | 6 x 5.5″ | M14 X 1.5 | Nut | 78.1mm |

| Chevy C2500 Truck HD (2WD, 8 Lug) | ’88-’00 | 8 x 6.5″ | M14 X 1.5 | Nut | 116.7mm |

| Chevy C3500 Truck (2WD) | ’88-’00 | 8 x 6.5″ | M14 X 1.5 | Nut | 116.7mm |

| Chevy Canyon (SL, SLE, SLT, ZQ8) | ’04-’08 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Chevy CK2500 & 3500 Truck (DRW) | ’88-’08 | 8 x 6.5″ | M14 X 1.5 | Nut | 116.7mm |

| Chevy Colorado, Canyon | ’04 & Older | 6 x 5.5″ | M12 X 1.5 | Nut | 100.7mm |

| GMC Denali (4X4) | ’92 & Older | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| GMC Jimmy | ’95-’02 | 5 x 4.75″ | M12 X 1.5 | Nut | 70.3mm |

| Chevy K1500 (4X4) | ’88-’98 | 6 x 5.5″ | M14 X 1.5 | Nut | 78.1mm |

| Chevy K2500 (4X4, 6 Lug) | ’88-’00 | 6 x 5.5″ | M14 X 1.5 | Nut | 78.1mm |

| Chevy K2500 (4X4, 8 Lug) | ’88-’00 | 8 x 6.5″ | M14 X 1.5 | Nut | 116.7mm |

| Chevy K3500 (4X4) | ’88-’00 | 8 x 6.5″ | M14 X 1.5 | Nut | 116.7mm |

| S-10, S-15 Blazer, Jimmy, Sonoma (2WD) | ’82-’04 | 5 x 4.75″ | M12 X 1.5 | Nut | 70.3mm |

| S-10, S-15 Blazer, Jimmy, Sonoma (2WD) | ’82 & Older | 5 x 4.75″ | M12 X 1.5 | Nut | 70.3mm |

| S-10, S-15 Blazer, Jimmy, Sonoma (4X4) | ’83 & Older | 5 x 4.75″ | M12 X 1.5 | Nut | 70.3mm |

| GMC Sierra 1500, Denali | ’99-’08 | 6 x 5.5″ | M14 X 1.5 | Nut | 78.1mm |

| GMC Sierra 2500 | ’99-’08 | 8 x 6.5″ | M14 X 1.5 | Nut | 116.7mm |

| GMC Sierra 3500 | ’99-’08 | 8 x 6.5″ | M14 X 1.5 | Nut | 116.7mm |

| Chevy Suburban (2WD) | ’71-’91 | 5 x 5″ | 1/2-RH | Nut | 78.3mm |

| Chevy Suburban (4X4) | ’71-’91 | 6 x 5.5″ | 7/16-RH | Nut | 78.3mm |

| Chevy Suburban 1500 HD | ’00-’08 | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy Suburban K2500 (4X4) | ’88-’99 | 8 x 6.5″ | M14 X 1.5 | Nut | 117mm |

| Chevy Suburban, Tahoe, Yukon (2WD) | ’00 & Older | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy Tahoe, Yukon (2WD) | ’92-’99 | 5 x 5″ | M14 X 1.5 | Nut | 78.1mm |

| Chevy Tahoe, Yukon | ’92 & Older | 6 x 5.5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy Tahoe, Yukon (2WD) | ’92-’99 | 5 x 5″ | M14 X 1.5 | Nut | 78.3mm |

| Chevy Tracker | ’98 & Older | 5 x 5.5″ | M12 X 1.25 | Nut | 108mm |

| Chevy Trailblazer (EXT) | ’02 & Older | 6 x 5″ | M12 X 1.5 | Nut | 78.3mm |

| Chevy Yukon 1500 (Hybrid) | ’00-’08 | 6 x 5.5″ | M14 X 1.5 | Nut | 78.1mm |

| Chevy Yukon | ’92-’99 | 5 x 5″ | M14 X 1.5 | Nut | 78.1mm |

| Chevy Yukon 2500 3/4 Ton (XL) | ’00-’06 | 8 x 6.5″ | M14 X 1.5 | Nut | 116.7mm |

| Chevy Yukon Denali 1500 | ’92-’08 | 6 x 5.5″ | M14 X 1.5 | Nut | 78.1mm |

| Dodge Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Dodge 1/2 and 3/4 Ton Trucks | ’79-’93 | 5 x 5.5″ | 1/2-RH | Nut | 77.8mm |

| Dodge 1/2 Ton Pickup and Van | ’49-’70 | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Dodge 1/2 Ton Pickup and Van | ’71-’85 | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Dodge D-50 & RAM-50 (Turbo Diesel) | ’79-’93 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Dodge Dakota | ’05 & Older | 5 x 5.5″ | 9/16-RH | Nut | 77.8mm |

| Dodge Dakota and Durango | ’91-’03 | 6 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Dodge Dakota and Durango | ’91-’04 | 6 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Dodge Dakota | ’05-’08 | 5 x 5.5″ | 9/16-RH | Nut | 77.8mm |

| Dodge Dakota(LE, HD) | ’87-’90 | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Dodge Dakota | ’87-’90 | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Dodge Ram 1/2 Ton Trucks | ’94-’01 | 5 x 5.5″ | 1/2-RH | Nut | 77.8mm |

| Dodge Ram 1/2 Ton Trucks | ’02 & Older | 5 x 5.5″ | 9/16-RH | Nut | 77.8mm |

| Dodge Ram 1/2 Ton Trucks | ’94-’01 | 5 x 5.5″ | 1/2-RH | Nut | 77.8mm |

| Dodge Ram 1/2 Ton Trucks | ’02 & Older | 5 x 5.5″ | 9/16-RH | Nut | 77.8mm |

| Dodge Ram 3/4 Ton Trucks | ’94 & Older | 8 x 6.5″ | 9/16-RH | Nut | 122.5mm |

| Dodge Ram 3/4 Ton Trucks | ’94 & Older | 8 x 6.5″ | 9/16-RH | Nut | 122.5mm |

| Ford Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Ford 1/2 Ton F-100 (2WD) | ’80-’85 | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Ford 1/2 Ton F-100, F-150 | ’54-’96 | 5 x 5.5″ | 1/2-RH | Nut | 86.7mm |

| Ford 1/2 Ton F-100, F-150 | ’54-’96 | 5 x 5.5″ | 1/2-RH | Nut | 87mm |

| Ford Bronco | ’66 & Older | 5 x 5.5″ | 1/2-RH | Nut | 86.7mm |

| Ford Bronco II | ’82-’90 | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Ford Bronco II | ’82-’90 | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Ford Excursion | ’00 & Older | 8 x 170mm | M14 X 1.5 | Nut | 124.9mm |

| Ford Excursion | ’00-’02 | 8 x 170mm | M14 X 2.0 | Nut | 124.9mm |

| Ford Excursion | ’03-’05 | 8 x 170mm | M14 X 1.5 | Nut | 124.9mm |

| Ford Expedition | ’97-’00 | 5 x 135mm | M12 X 1.75 | Nut | 87mm |

| Ford Expedition | ’97-’00 | 5 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford Expedition | ’01-’02 | 5 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford Expedition | ’03 & Older | 6 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford Expedition | ’03-’08 | 6 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford Explorer (Sport Trac) | ’90-’01 | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Ford Explorer (Sport Trac) | ’02 & Older | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Ford Explorer (Sport Trac) | ’02-’08 | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Ford Explorer (Sport Trac) | ’90-’01 | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Ford F-150 Harley | ’06-’08 | 6 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford F-150 | ’97-’00 | 5 x 135mm | M12 X 1.75 | Nut | 87mm |

| Ford F-150 | ’97-’00 | 5 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford F-150 | ’04 & Older | 6 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford F-150 (’04 Heritage) | ’01-’04 | 5 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford F-150 (’04 Heritage, Lightning) | ’99-’04 | 5 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford F-150 (2WD) | ’01-’03 | 5 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford F-150 (4X4) | ’97-’00 | 5 x 135mm | 12 X 1.75 | Nut | 87mm |

| Ford F-150 (4X4) | ’01-’03 | 5 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford F-150 (XLT FX4 Lariat) | ’04-’08 | 6 x 135mm | M14 X 2.0 | Nut | 87mm |

| Ford F-150 (XL, Heavy Duty) | ’04-’07 | 7 x 150mm | M14 X 2.0 | Nut | 87mm |

| Ford F-150 (XL, Heavy Duty) | ’04 & Older | 7 x 150mm | M14 X 2.0 | Nut | 87mm |

| Ford F-250 & F-350 Super Duty | ’99-’04 | 8 x 170mm | M14 X 2.0 | Nut | 124.9mm |

| Ford F-250 & F-350 Super Duty | ’88-’97 | 8 x 6.5″ | 9/16, 1/2 | Nut | 124.9mm |

| Ford F-250 & F-350 Super Duty | ’99-’04 | 8 x 170mm | M14 X 2.0 | Nut | 124.9mm |

| Ford F-250 & F-350 Super Duty | ’05-’08 | 8 x 170mm | M14 X 1.5 | Nut | 124.9mm |

| Ford F-250 & F-350 Super Duty (DRW) | ’88-’98 | 8 x 6.5″ | 16-Sep | Nut | 124.9mm |

| Ford F-250 & F-350 Super Duty (DRW) | ’99-’07 | 8 x 170mm | M14 X 2.0 | Nut | 124.9mm |

| Ford F-250 & F-350 Super Duty (DRW) | ’06-’08 | 8 x 200mm | M14 X 2.0 | Nut | 160mm |

| Ford F-250 & F-350 Super Duty (DRW) | ’04 & Older | 8 x 170mm | M14 X 1.5 | Nut | 124.9mm |

| Ford F-350 Harley Davidson | ’05-’08 | 8 x 170mm | M14 X 1.5 | Nut | 124.9mm |

| Ford Ranger (2WD) | ’81 & Older | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Ford Ranger (2WD) | ’81-’08 | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Ford Ranger (4X4) | ’73 & Older | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Ford Ranger (4X4) | ’83-’08 | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Hummer Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Hummer H1 | All | 8 x 165mm | M14 X 1.5 | Nut | 117mm |

| Hummer H2 | ’03-’08 | 8 x 6.5″ | M14 X 1.5 | Nut | 117mm |

| Hummer H2 | ’03 & Older | 8 x 165mm | M14 X 1.5 | Nut | 117mm |

| Hummer H3 (H3X, Alpha, Luxury) | ’06-’08 | 6 x 5.5″ | M12 X 1.5 | Nut | 100mm |

| Isuzu Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Isuzu Trooper | ’92-’03 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Isuzu Trooper | ’92-’96 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Isuzu Trooper II | ’84-’91 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Isuzu I-280, I-290, I-350, I-370 Pickup | ’06-’08 | 6 x 5.5″ | M12 X 1.5 | Nut | 100mm |

| Isuzu Pickup | ’80-’96 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Jeep Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Jeep Cherokee, Grand Wagoneer | ’74-’92 | 6 x 5.5″ | 7/16-RH | Nut | 108mm |

| Jeep All Models, CJ | ’46-’85 | 5 x 5.5″ | 1/2-RH | Nut | 108mm |

| Jeep Cherokee | ’80 & Older | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Cherokee, Wrangler | ’80-’06 | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Commanche, Chief | ’80-’93 | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Commander | ’06-’08 | 5 x 5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Compass | ’07-’08 | 5 x 4.5″ | M12 X 1.5 | Nut | 67.1mm |

| Jeep Grand Cherokee | ’93-’98 | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Grand Cherokee | ’99 & Older | 5 x 5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Grand Cherokee | ’93-’98 | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Grand Cherokee (SRT8) | ’99-’08 | 5 x 5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Cherokee, Grand Wagoneer | ’74-’92 | 6 x 5.5″ | 7/16-RH | Nut | 108mm |

| Jeep Liberty | ’08 | 5 x 4.5″ | M12 X 1.5 | Nut | 67.1mm |

| Jeep Liberty | ’02 & Older | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Liberty | ’02-’07 | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Patriot | ’07-’08 | 5 x 4.5″ | M12 X 1.5 | Nut | 67.1mm |

| Jeep Prospector | ’08 | 5 x 4.5″ | M12 X 1.5 | Nut | 67.1mm |

| Jeep Wrangler | ’80-’06 | 5 x 4.5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Wrangler | ’07 & Older | 5 x 5″ | 1/2-RH | Nut | 71.5mm |

| Jeep Wrangler (Sahara, Rubicon) | ’07-’08 | 5 x 5″ | 1/2-RH | Nut | 71.5mm |

| Kaiser Military Trucks | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Kaiser 2.5 Ton (Rockwell Axles) | All | 6 x 8.750″ | 3/4″-16 | Nut |

| Land Rover Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Land Rover LR2 | ’08 | 5 x 4.25″ | M14 X 1.5 | Nut | 63.4mm |

| Land Rover Freelander (SE, SE3) | ’02-’05 | 5 x 4.5″ | M12 X 1.5 | Nut | 64.1mm |

| Land Rover Discovery, Discovery II | ’99-’04 | 5 x 120mm | M14 X 1.5 | Nut | 72.56mm |

| Land Rover LR3 (SE, HSE) | ’05-’08 | 5 x 120mm | M14 X 1.5 | Nut | 72.56mm |

| Land Rover Range Rover | ’96-’02 | 5 x 120mm | M14 X 1.5 | Nut | 72.56mm |

| Land Rover Range Rover (HSE, S/C) | ’03-’08 | 5 x 120mm | M14 X 1.5 | Nut | 72.56mm |

| Land Rover Range Rover (Sport, HSE, S/C) | ’06-’08 | 5 x 120mm | M14 X 1.5 | Nut | 72.56mm |

| Land Rover Discovery | ’99 & Older | 5 x 120mm | M14 X 1.5 | Nut | 72.56mm |

| Land Rover Range Rover | ’92 & Older | 5 x 120mm | M14 X 1.5 | Nut | 72.56mm |

| Land Rover Range Rover | ’99-’02 | 5 x 120mm | M14 X 1.5 | Nut | 72.56mm |

| Land Rover Freelander | ’02 & Older | 5 x 4.5″ | M12 X 1.5 | Nut | |

| Land Rover Defender, Discovery, Range Rover | ’99 & Older | 5 x 6.5″ | M16 X 1.5 | Nut |

| Mazda Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Mazda 2600 Pickup | ’77-’93 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Mazda B-2000, 2200, 2300 Pickup | ’77-’93 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Mazda B-2000, 2200,2300,2600 Pickup | ’77-’93 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Mazda B-2500, 3000, 4000 Pickup | ’93 & Older | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Mazda B-2500, 3000, 4000 Pickup | ’93-’08 | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Mazda Pickup | ’93 & Older | 5 x 4.5″ | 1/2-RH | Nut | 70.3mm |

| Mercedes Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Mercedes G-Wagon | All | 5 x 130mm | M14 X 1.5 | Bolt | 84.1mm |

| Mitsubishi Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Mitsubishi Montero | ’83-’00 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Mitsubishi Montero | ’92-’06 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Mitsubishi Montero | ’01 & Older | 6 x 5.5″ | M12 X 1.5 | Nut | 67.1mm |

| Mitsubishi Montero Sport | ’92 & Older | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Mitsubishi Montero Sport | ’92-’04 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Mitsubishi Raider (LS, Durocross) | ’06-’08 | 5 x 5.5″ | 16-Sep | Nut | 77.8mm |

| Nissan Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Nissan Armada | ’04 & Older | 6 x 5.5″ | M12 X 1.25 | Nut | 78mm |

| Nissan Armada (2WD, 4X4) | ’04-’08 | 6 x 5.5″ | M12 X 1.25 | Nut | 77.8mm |

| Nissan Pathfinder | ’87-’04 | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Pathfinder | ’05 & Older | 6 x 4.5″ | M12 X 1.25 | Nut | 66.1mm |

| Nissan Pathfinder (2WD, 4X4) | ’87-’04 | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Pathfinder (LE, S, SE, XE ) | ’05-’08 | 6 x 4.5″ | M12 X 1.25 | Nut | 66.1mm |

| Nissan Pathfinder Armada | ’04 & Older | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Xterra | ’00 & Older | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Xterra (2WD, 4X4) | ’00-’04 | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Xterra (2WD, 4X4) | ’05-’08 | 6 x 4.5″ | M12 X 1.25 | Nut | 66.1mm |

| Nissan Frontier (2WD) | ’87-’96 | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Frontier (4X4) | ’87-’96 | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Frontier | ’98 & Older | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Frontier (Nismo, LE, SE, XE) | ’05-’08 | 6 x 4.5″ | M12 X 1.25 | Nut | 66.1mm |

| Nissan Frontier (SC, SE, SVE, XE) | ’98-’04 | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Pickup | ’73-’86 | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Pickup (2WD, 4X4) | ’73-’86 | 6 x 5.5″ | M12 X 1.25 | Nut | 100mm |

| Nissan Titan | ’04 & Older | 6 x 5.5″ | M12 X 1.25 | Nut | 78mm |

| Nissan Titan (LE, SE, XE, LE, W, PRO 4X) | ’04-’08 | 6 x 5.5″ | M12 X 1.25 | Nut | 78.1mm |

| Suzuki Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Suzuki Samurai | ’86-’93 | 5 x 5.5″ | M12 X 1.25 | Nut | 108mm |

| Suzuki Sidekick | ’89-’96 | 5 x 5.5″ | M12 X 1.25 | Nut | 108mm |

| Suzuki Sidekick | ’96-’97 | 5 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Toyota Trucks and SUVs | Year | Bolt Pattern | Stud Size | Lug Style | Center Bore |

| Toyota Sequoia | ’08 | 5 x 150mm | M14 X 1.5 | Nut | 110mm |

| Toyota Landcruiser | ’69-’92 | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota 4-Runner | ’86-’02 | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota Landcruiser | ’93-’97 | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota Landcruiser | ’98 & Older | 5 x 150mm | M14 X 1.5 | Nut | 110mm |

| Toyota Landcruiser | ’98-’08 | 5 x 150mm | M14 X 1.5 | Nut | 110mm |

| Toyota 4-Runner | ’00 & Older | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota Highlander | ’01 & Older | 5 x 4.5″ | M12 X 1.5 | Nut | 60.1mm |

| Toyota Sequoia | ’01 & Older | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota Sequoia (2WD, 4X4) | ’01-’07 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Toyota Highlander Hybrid | ’01-’08 | 5 x 4.5″ | M12 X 1.5 | Nut | 60.1mm |

| Toyota 4-Runner (V6, V8) | ’03 & Older | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota 4-Runner (V6, V8) | ’03-’08 | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota FJ Cruiser | ’07-’08 | 6 x 5.5″ | M12 X 1.5 | Nut | 108mm |

| Toyota Pickup (2WD) | ’80-’95 | 5 x 4.5″ | M12 X 1.5 | Nut | 60.1mm |

| Toyota Pickup (4×4) & 4-Runner | ’80-’95 | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota T-100 | ’93-’96 | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota Tacoma (4X4, Pre-Runner) | ’95 & Older | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota Tacoma (2WD, Not Pre-Runner) | ’95-’04 | 5 x 4.5″ | M12 X 1.5 | Nut | 60.1mm |

| Toyota Tacoma (2WD, 4X4, Pre-Runner) | ’95-’04 | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota Tacoma (2WD, Not Pre-Runner) | ’95-’97 | 5 x 4.5″ | M12 X 1.5 | Nut | 67.1mm |

| Toyota Tundra | ’99 & Older | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota Tundra (2WD, 4X4) | ’99-’06 | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota Tacoma (2WD, 15″ Wheels) | ’05-’08 | 5 x 4.5″ | M12 X 1.5 | Nut | 60.1mm |

| Toyota Tacoma (2WD, 16″ Wheels) | ’05-’08 | 6 x 5.5″ | M12 X 1.5 | Nut | 106mm |

| Toyota Tacoma (X-Runner, W, OE 18″) | ’05-’08 | 5 x 4.5″ | M12 X 1.5 | Nut | 60.1mm |

| Toyota Tundra (2WD, 4X4) | ’07-’08 | 5 x 150mm | M14 X 1.5 | Nut | 110mm |

Above charts are courtesy of: crawlpedia.com

WHICH TYPE OF WHEEL IS RIGHT FOR YOU? Steel, cast-aluminum or forged-aluminum. Need help understanding these different types of wheels, so you can decide which wheel is right for you?

Harry Wagner, a skilled off-roader and author for many sources of off-road media has written a great article for the FOURWHEELER network and gave us permission to share it with you. If you have not met Harry or seen his articles, and photography, you need to. Check him out using the link at the bottom of this blog and follow him at Harry Situations.

Below is a copy of his article to help you make your decision.

FIND OUT WHICH WHEEL IS RIGHT FOR YOUR JEEP

By: Harry Wagner

Few upgrades make the same visual statement on your Jeep as your selection of tires and wheels. Determining which wheel material and construction to run isn’t always straightforward though. There are a number of factors to consider, including cost, strength, weight, aesthetics, diameter, width, and backspacing. The order of importance might vary from person to person, but those are usually the deciding factors when shopping for new wheels.

Steel Wheels

Steel wheels have been used on Jeeps since they were spelled with a lowercase

“j.” The biggest benefits of steel wheels are that they are inexpensive and

strong. You can grind a steel wheel up against a rock and the only thing you

typically have to worry about is cutting yourself, not whether or not it still

holds air. Should you manage to bend a steel wheel, it can typically be beaten

back into shape with a hammer. Also, reinforcing rings can be easily welded on

to the circumference of the wheel to strengthen it.

Steel wheels, like these from US Wheel, are strong and inexpensive, making them perfect for a dedicated rockcrawler. They are also available with shallow backspacing, which widens the track width and adds stability and clearance but also increases steering effort.

Steel wheels are stamped, and as a result, they are typically thinner than a comparable aluminum wheel, making brake fitment easier in tight applications. Steel wheels come in a variety of diameters (up to 17 inches), widths, and backspacing options, although their style choices are limited to whether you want spokes or round holes and black or white or chrome finish. If there is a downside to steel wheels, it is that they are heavy. A typical steel wheel weighs approximately 20 percent more than a similar-sized cast-aluminum wheel.

Cast-Aluminum Wheels

The price gap between cast-aluminum and steel wheels has closed in recent

years, with aluminum wheels offered in far more styles and sizes than steel

wheels. While rivets and bolts have become popular accessories, they are

generally cosmetic, and nearly all cast-aluminum wheels use one-piece

construction for strength and simplicity. The downside of cast-aluminum, when

compared to steel, is that when subjected to hard impacts, aluminum will break

rather than bend. In either case, the wheel will need to be replaced, but it is

easier to limp off the trail with a bent steel wheel than a cracked aluminum

one.

The Mickey Thompson Classic III is a cast-aluminum wheel that is available in a variety of sizes and bolt patterns. The maximum load of the Classic III is more a function of the bolt pattern than the wheel construction. The 5-lug Classic IIIs are rated at 1,900 pounds each, while 8-lug Classic IIIs are rated at 3,250 pounds each, with both using the same construction.

Cast-aluminum wheels are formed by pouring molten aluminum into a mold and machining the surface of the wheel into specification. The liquid aluminum can be poured into the mold directly (gravity cast) or under pressure (low-pressure casting), with the advantage of low-pressure-cast wheel being a more consistent density, thus increasing strength. Cast-aluminum wheels are generally lighter than a comparably sized steel wheel. Weight might not seem like a huge consideration on a Jeep with 1-ton axles and 40-inch-tall tires that is used on the trail, but lighter rolling stock (the combination of the tire and wheel) will improve acceleration and braking and decrease the likelihood of breaking axle components.

Forged-Aluminum Wheels

Forged wheels are both lighter and stronger than either cast-aluminum or steel, and if they do become damaged, they bend and can typically still limp off the trail to be repaired once you return home. So why don’t we see more forged-aluminum wheels on Jeeps? The downside to forged wheels is that they are diffcult to manufacture, and as result, they expensive. Forged wheels are also less common than cast-aluminum wheels. Both Weld and Centerline offer a full line of forged wheels, while other manufacturers such as Raceline and Fuel have both forged and cast-aluminum wheel offerings.

Fuel offers their Trophy wheel in either cast or forged construction, as a beadlock or fauxlock, to fit any budget and application. The cast-aluminum Trophy wheels are comparable in cost and load rating to traditional steel wheels in a 17 inch diameter.

Forged wheels start out as a large mass of aluminum that is formed between two dies, resulting in a density and grain structure that is stronger than a cast-aluminum wheel. Additionally, most cast wheels are constructed from A-356 aluminum, which is only about 60 percent as strong as the 6000-series alloys used for forged wheels. Forged wheels can be either hot forged, which is a faster, easier process, or cold forged, which is the strongest but most expensive, manufacturing technique.

Are Beadlocks Right for You?

Beadlock wheels are available in steel, cast aluminum, and forged aluminum.

They can be manufactured as a beadlock from inception or retrofitted onto an

existing wheel. Beadlocks also look really cool, which explains the number of

faux beadlock wheels on the market. The advantage of actual beadlocks is that

they to physically clamp the tire bead to the wheel and allow you to run

single-digit air pressures on your Jeep. This provides improved floatation in

the sand and snow and allows the tire to conform to rocks and other obstacles

on the trail. Just like any other specialized piece of equipment, from locking

differentials to winches, beadlock wheels require more maintenance than a

standard wheel. They are also often not legal for use on public roads. The

bolts should be retorqued after every wheeling trip and replaced if they are

damaged or broken.

Unlike traditional beadlock wheels that use a ring to clamp the tire bead to the wheel, Hutchinson Rock Monsters are two-piece cast-aluminum wheels with an inner liner between the tire beads that keep the tire on the wheel at low pressure. These wheels use the same bead retention system as military HMMWV wheels, which are also manufactured by Hutchison.

Harry Wagner: Harry

Situations, Freelance Writing & Photography

Recent Posts

-

Choosing the right wheel and tire

Trying to find the right wheel for your vehicle, terrain or application? We can help wit …13th Sep 2018